Coming Up

-

GTC Drone Workshop

27 Jan 26 @ Online

-

DJI Ronin 4D Masterclass: Experience Cinematic Freedom

4 Feb 26 @ London, W1W 6RN

-

DJI Ronin 4D Masterclass: Experience Cinematic Freedom - March

4 Mar 26 @ London, W1W 6RN

-

MPTS 2026

13 May 26 @ London, W14 8UX

Sponsor News

Zerb 91 rolls off the press!

Rob Emmanuel with the print proof of Zerb 91 shown to him by Holywell Press MD Ben Burrows and print manager Paul Bethell.

Rob Emmanuel with the print proof of Zerb 91 shown to him by Holywell Press MD Ben Burrows and print manager Paul Bethell.

New Zerb Managing Editor Rob Emmanuel paid his first visitor to the magazine's printers, Holywell Press in Oxford, and designers, Toast Design, Banbury to see the magazine through its final stages before delivery this week.

Rob was there to approve the proofs of first the cover section and then all the other pages of his first issue at the helm – Zerb 91. Once the proofs were all signed off and a couple of last-minute corrections made in the quest for perfection(!), it was down to see the first of 3800 copies of the cover go through the press.

Holywell MD Ben Burrows kindly took the time to explain all the processes involved to Rob.

|

Print manager Paul Bethell with the first print proofs of the cover. |

|

|

Zerb is printed on FSC certified (long grain gloss) paper sourced from Europe. Zerb is printed on FSC certified (long grain gloss) paper sourced from Europe. |

Ben demonstrates the intricacies of folding the sections of pages... Ben demonstrates the intricacies of folding the sections of pages... |

|

|

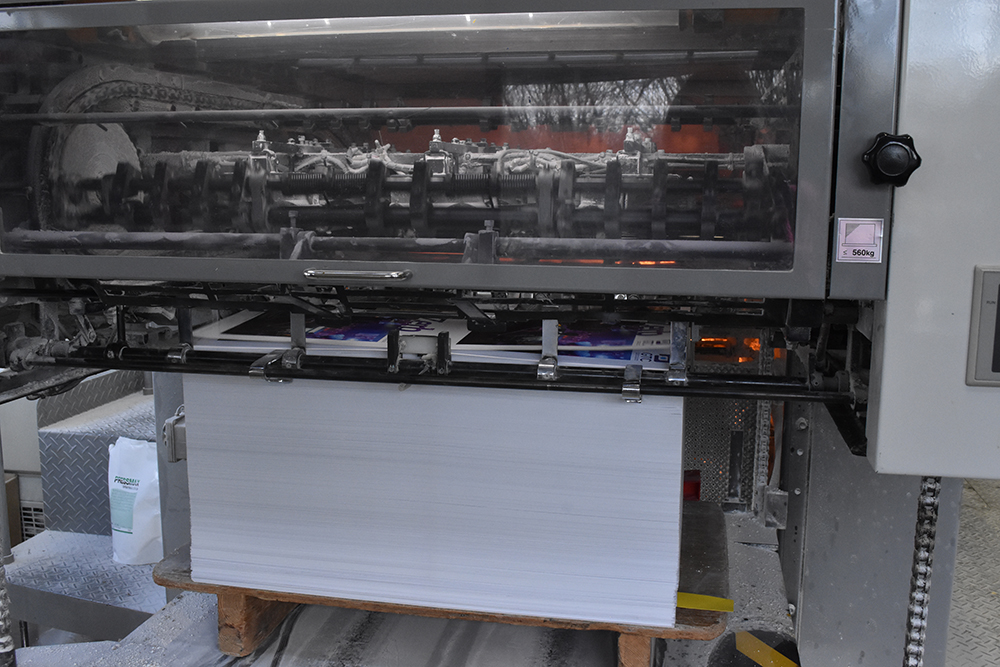

Back on the Sakurai 5-stage press (four colours plus varnish etc.) the cover is now being printed. |

|

Rob learning about the 'black art' of printing! |

|

After the sections have been compiled, they are stapled (or stitched) together. |

Once printed, the magazine will be trimmed to size on this machine. Once printed, the magazine will be trimmed to size on this machine. |

Paul checks the litho plates – fortunately this once dangerous process is now H&S controlled and an alarm was sounding as he got in amongst the machine! |

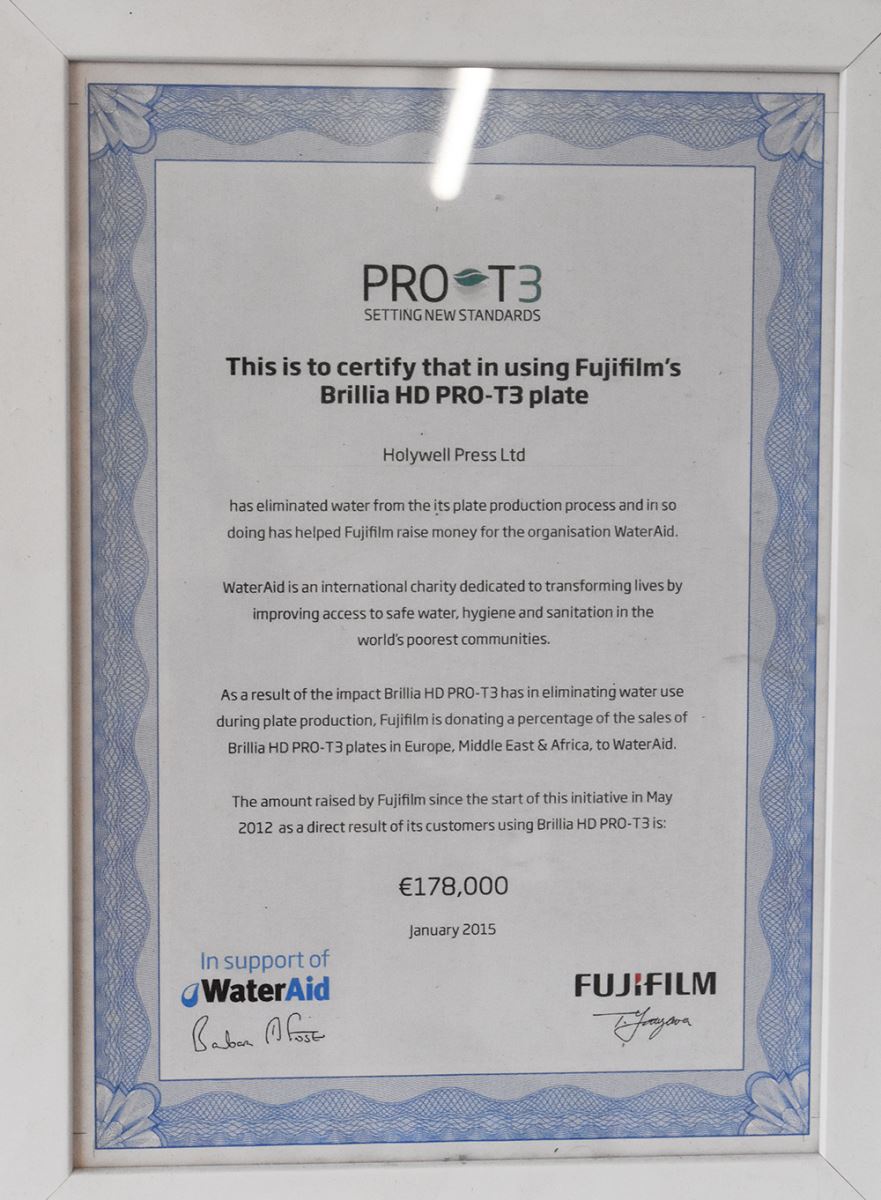

All paper used by Holywell is sourced from sustainable sources with Forest Stewardship Council (FSC) certification. Holywell also contributes to The Woodland Trust native woodland planting scheme. The inks used are vegetable rather than mineral based so are also a more environmentally friendly option, and the use of water in the plate production process has been minimised and money is donated to Water Aid. |

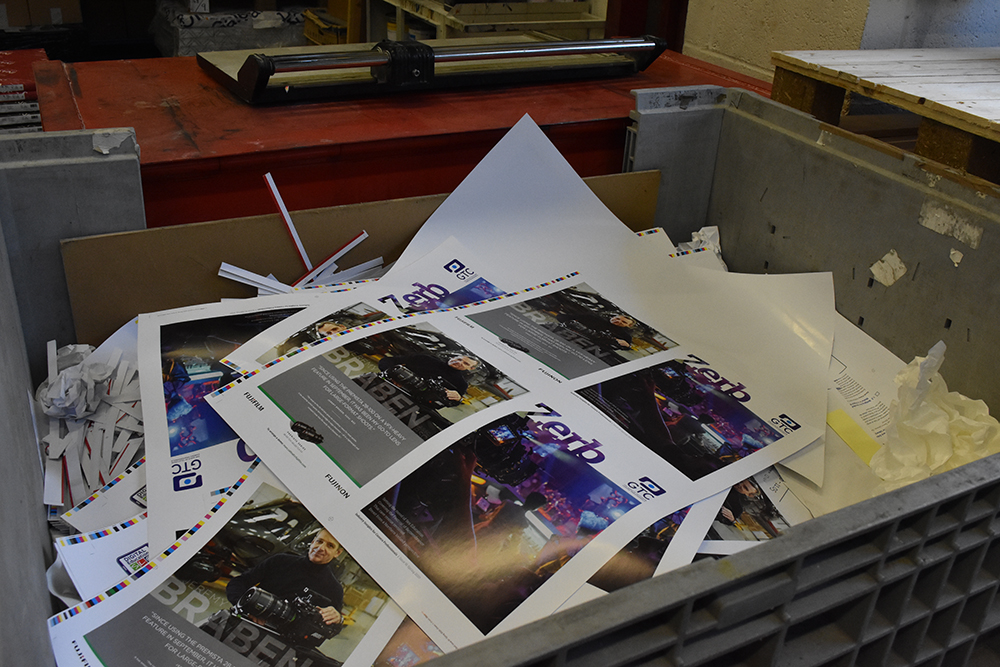

Residue from the trimming machine. |

And the first covers are coming through! And the first covers are coming through! |

|

|

||

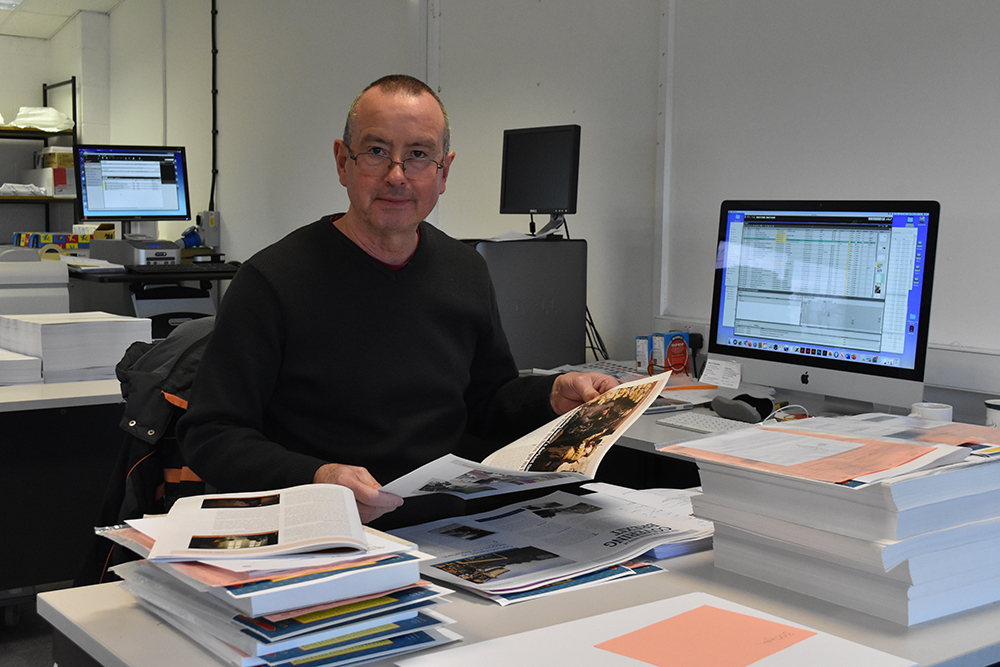

Meanwhile, back in the production office, Chris Nash has prepared a set of digital proofs of all the other pages for checking. After a few last corrections, the magazine is cleared to go on the presses. Meanwhile, back in the production office, Chris Nash has prepared a set of digital proofs of all the other pages for checking. After a few last corrections, the magazine is cleared to go on the presses. |

||

Where to next?

Coming Up

-

GTC Drone Workshop

27 Jan 26 @ Online

-

DJI Ronin 4D Masterclass: Experience Cinematic Freedom

4 Feb 26 @ London, W1W 6RN

-

DJI Ronin 4D Masterclass: Experience Cinematic Freedom - March

4 Mar 26 @ London, W1W 6RN

-

MPTS 2026

13 May 26 @ London, W14 8UX

Rob approves his first Zerb cover section for printing with Ben.

Rob approves his first Zerb cover section for printing with Ben. Explaining how the lithographic plates are prepared for printing.

Explaining how the lithographic plates are prepared for printing. ... and this is the machine that compiles sections of pages in the correct order.

... and this is the machine that compiles sections of pages in the correct order.

Time for a top-up of ink – Paul adds more.

Time for a top-up of ink – Paul adds more.

The first pile of the 3800 Zerb 91 covers that will eventually be printed.

The first pile of the 3800 Zerb 91 covers that will eventually be printed.